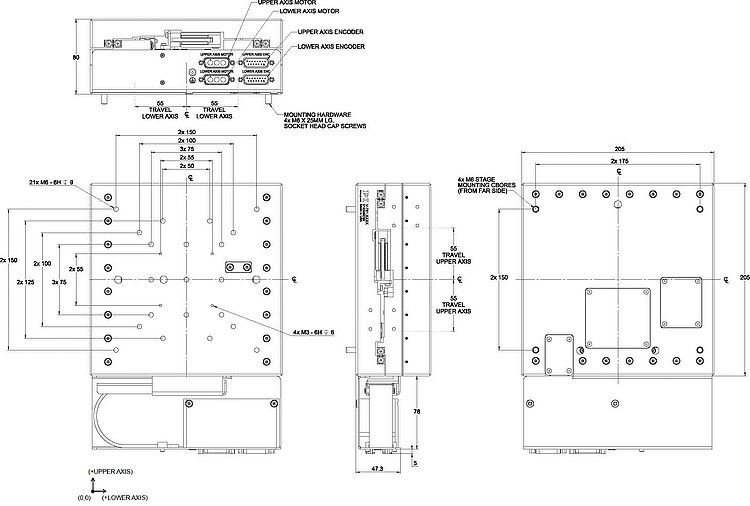

Ultra-precision direct drive XY stage; ironless 3-phase linear motor; 110 mm × 110 mm travel range (X × Y); 100 N load capacity; 500 mm/s × 500 mm/s maximum velocity; incremental linear encoder, 1 nm sensor resolution, sin/cos, 1 V peak-to-peak

V-781 Ultra-Precision Direct Drive XY Stage

Ideal for Scanning, Measuring, and Imaging

- Travel ranges of 110 mm, 210 mm, and 310 mm

- Direct drive motor for efficient, dynamic performance

- Crossed-roller bearings for optimum straightness and flatness

- Incremental or absolute encoder for the best accuracy, repeatability, and safety (with absolute encoder)

Product overview

The monolithic XY linear stages of the V-781 family are designed for accuracy, precision, low maintenance, and ease of use. They offer a more compact design and, thanks to their wider base, better straightness, less yaw, and greater rigidity than stacked systems consisting of two individual linear tables.

V-781 nanopositioning stages offer an outstanding positioning accuracy and repeatability. The absolute encoder models provide not only 1 nm resolution, but also a safe and efficient start, not requiring initialization or a referencing move.

Thanks to their powerful, non-cogging, direct drive motor and the crossed roller bearings, XY stages of the V-781 family are ideally suited for use in production environments. The ultra-precision cross roller bearings are intended to be low maintenance for the life of the stage.

3-phase motors for higher dynamics and friction-free, maintenance-free operation

The 3-phase linear motors driving the V-781 stage family transfer their force directly and friction-free to the motion platform. This eliminates backlash and play that can result from mechanical components like gears and screws in the drivetrain. Ideal for high-velocity, high-acceleration applications, these motors feature a maintenance-free, friction-free design, ensuring longevity in demanding 24/7 operations. The controller's current limit settings allow easy motor disablement, preventing damage to the stage or the application.

Crossed roller bearings for higher load capacity and precision, as well as a longer service life

Crossed roller bearings offer a superior level of smoothness, straightness, and flatness, close to air bearing performance. By replacing the point contact of ball bearings with a line contact, rollers become considerably stiffer, requiring less preload. This reduction in friction enables smoother running and higher accuracy. Crossed roller bearings can also support higher vertical and moment loads. The anti-creep mechanism prevents roller drift, enhancing reliability. Cleanroom grease is applied for low-maintenance operation.

Incremental and absolute encoder options

V-781 stages are equipped with linear encoders that measure positions with maximum accuracy directly on the motion platform. enhancing linearity and ensuring immunity to mechanical play and elastic deformation which can result from indirect measuring methods. Incremental encoders with 1 Vpp sine/cosine signal output require a home signal to initiate. In contrast, absolute measuring linear encoders offer explicit position information, enabling immediate determination of the position. This eliminates the need for referencing during switch-on, enhancing both efficiency and safety during operation.

Selection of the right precision linear stage and controller

Selecting the right linear stage is pivotal for optimal performance in high-precision motion applications, such as semiconductor inspection and photonics alignment. Factors such as resolution, guiding accuracy, and repeatability must be carefully considered. The V-781 linear stage family provides extremely high geometric accuracy (flatness, straightness, pitch, and yaw) along with ±70 nanometers bi-directional repeatability. With high dynamic properties, featuring 1 g acceleration and 1 m/s velocity, these fast and accurate motorized stages are ideal for automation of highly accurate positioning tasks required for the mass production of precision devices.

Partnered with PI’s A-8xx series motion controllers, these stages achieve unparalleled motion performance. PI’s EtherCAT-based controllers offer remarkable flexibility, facilitating the seamless integration of third-party equipment compatible with EtherCAT. Advanced algorithms in the A-8xx series motion controllers, such as PILOT, allow for higher dynamics with reduced motor currents, virtually increasing the motor’s force constant. Choose the V-781 for precision, reliability, and efficiency in your motion applications.

Accessories and options

- Encoder type: incremental encoder with 1 Vpp sin/cos signal output or absolute encoder with BiSS output

- Multi-axis ACS motion controllers and servo drives, integrated or distributed

- Cables compatible with A-8xx, the series of ACS-based controllers

- Multi-axis XYZ stage assemblies

- Granite base

Application fields

Metrology Surface profile and characterization. Semiconductor test and inspection. Sample inspection. Precision micro-assembly. Research. Biotechnology. Semiconductor industry. General automation. Device assembly. Laser micro-processing. Pick and place.

Specifications

Specifications

| Motion | V-781.110A1 | V-781.210A1 | V-781.310A1 | V-781.110B1 | V-781.210B1 | V-781.310B1 | Tolerance |

|---|---|---|---|---|---|---|---|

| Active axes | X ǀ Y | X ǀ Y | X ǀ Y | X ǀ Y | X ǀ Y | X ǀ Y | |

| Travel range in X | 110 mm | 210 mm | 310 mm | 110 mm | 210 mm | 310 mm | |

| Travel range in Y | 110 mm | 210 mm | 310 mm | 110 mm | 210 mm | 310 mm | |

| Acceleration in X, unloaded | 5 m/s² | 10 m/s² | 10 m/s² | 5 m/s² | 10 m/s² | 10 m/s² | max. |

| Acceleration in Y, unloaded | 5 m/s² | 10 m/s² | 10 m/s² | 5 m/s² | 10 m/s² | 10 m/s² | max. |

| Maximum velocity in X, unloaded | 500 mm/s | 1000 mm/s | 1000 mm/s | 500 mm/s | 1000 mm/s | 1000 mm/s | |

| Maximum velocity in Y, unloaded | 500 mm/s | 1000 mm/s | 1000 mm/s | 500 mm/s | 1000 mm/s | 1000 mm/s | |

| Straightness error E_XY (straightness) | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | max. |

| Straightness error E_YX (straightness) | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | max. |

| Straightness error E_ZX (flatness) | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | max. |

| Straightness error E_ZY (flatness) | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | ± 0.75 µm | max. |

| Angular error E_AY (pitch) | ± 25 µrad | ± 50 µrad | ± 75 µrad | ± 25 µrad | ± 50 µrad | ± 75 µrad | max. |

| Angular error E_BX (pitch) | ± 25 µrad | ± 50 µrad | ± 75 µrad | ± 25 µrad | ± 50 µrad | ± 75 µrad | max. |

| Angular error E_CX (yaw) | ± 25 µrad | ± 40 µrad | ± 50 µrad | ± 25 µrad | ± 40 µrad | ± 50 µrad | max. |

| Angular error E_CY (yaw) | ± 25 µrad | ± 40 µrad | ± 50 µrad | ± 25 µrad | ± 40 µrad | ± 50 µrad | max. |

| Positioning | V-781.110A1 | V-781.210A1 | V-781.310A1 | V-781.110B1 | V-781.210B1 | V-781.310B1 | Tolerance |

| Positioning accuracy in X, calibrated | ± 0.17 µm | ± 0.17 µm | ± 0.17 µm | ± 0.17 µm | ± 0.17 µm | ± 0.17 µm | max. |

| Positioning accuracy in Y, calibrated | ± 0.17 µm | ± 0.17 µm | ± 0.17 µm | ± 0.17 µm | ± 0.17 µm | ± 0.17 µm | max. |

| Bidirectional repeatability in X | 0.07 µm | 0.07 µm | 0.07 µm | 0.07 µm | 0.07 µm | 0.07 µm | max. |

| Bidirectional repeatability in Y | 0.07 µm | 0.07 µm | 0.07 µm | 0.07 µm | 0.07 µm | 0.07 µm | max. |

| Reference switch | Index in the middle of the travel range, 1 V peak-peak | Index in the middle of the travel range, 1 V peak-peak | Index in the middle of the travel range, 1 V peak-peak | — | — | — | |

| Integrated sensor | Incremental linear encoder | Incremental linear encoder | Incremental linear encoder | Absolute linear encoder | Absolute linear encoder | Absolute linear encoder | |

| Sensor signal | Sin/cos, 1 V peak-peak | Sin/cos, 1 V peak-peak | Sin/cos, 1 V peak-peak | BiSS-C, 32-bit | BiSS-C, 32-bit | BiSS-C, 32-bit | |

| Sensor resolution | 1 nm | 1 nm | 1 nm | 1 nm | 1 nm | 1 nm | |

| Drive properties | V-781.110A1 | V-781.210A1 | V-781.310A1 | V-781.110B1 | V-781.210B1 | V-781.310B1 | Tolerance |

| Drive type | Ironless 3-phase linear motor | Ironless 3-phase linear motor | Ironless 3-phase linear motor | Ironless 3-phase linear motor | Ironless 3-phase linear motor | Ironless 3-phase linear motor | |

| Nominal voltage | 60 V | 60 V | 60 V | 60 V | 60 V | 60 V | |

| Nominal current, RMS | 1.7 A | 5.1 A | 5.1 A | 1.7 A | 5.1 A | 5.1 A | typ. |

| Peak current, RMS | 6.2 A | 17.5 A | 17.5 A | 6.2 A | 17.5 A | 17.5 A | typ. |

| Drive force in X | 20 N | 140 N | 140 N | 20 N | 140 N | 140 N | typ. |

| Drive force in Y | 20 N | 140 N | 140 N | 20 N | 140 N | 140 N | typ. |

| Peak force in X | 72 N | 480 N | 480 N | 72 N | 480 N | 480 N | |

| Peak force in Y | 72 N | 480 N | 480 N | 72 N | 480 N | 480 N | |

| Force constant | 11.4 N/A | 27.5 N/A | 27.5 N/A | 11.4 N/A | 27.5 N/A | 27.5 N/A | |

| Resistance phase-phase | 2.4 Ω | 1.28 Ω | 1.28 Ω | 2.4 Ω | 1.28 Ω | 1.28 Ω | typ. |

| Inductance phase-phase | 0.38 mH | 1.02 mH | 1.02 mH | 0.38 mH | 1.02 mH | 1.02 mH | |

| Back EMF phase-phase | 9.3 V·s/m | 22.5 V·s/m | 22.5 V·s/m | 9.3 V·s/m | 22.5 V·s/m | 22.5 V·s/m | max. |

| Pole pitch N-N | 16 mm | 42 mm | 42 mm | 16 mm | 42 mm | 42 mm | |

| Mechanical properties | V-781.110A1 | V-781.210A1 | V-781.310A1 | V-781.110B1 | V-781.210B1 | V-781.310B1 | Tolerance |

| Permissible push force in Z | 100 N | 500 N | 500 N | 100 N | 500 N | 500 N | max. |

| Moved mass in X, unloaded | 6.5 kg | 25 kg | 46 kg | 6.5 kg | 25 kg | 46 kg | |

| Moved mass in Y, unloaded | 3 kg | 11 kg | 20 kg | 3 kg | 11 kg | 20 kg | |

| Bearing type | Crossed roller bearings | Crossed roller bearings | Crossed roller bearings | Crossed roller bearings | Crossed roller bearings | Crossed roller bearings | |

| Overall mass | 7 kg | 38 kg | 62 kg | 7 kg | 38 kg | 62 kg | |

| Material | Aluminum, hard anodized | Aluminum, hard anodized | Aluminum, hard anodized | Aluminum, hard anodized | Aluminum, hard anodized | Aluminum, hard anodized | |

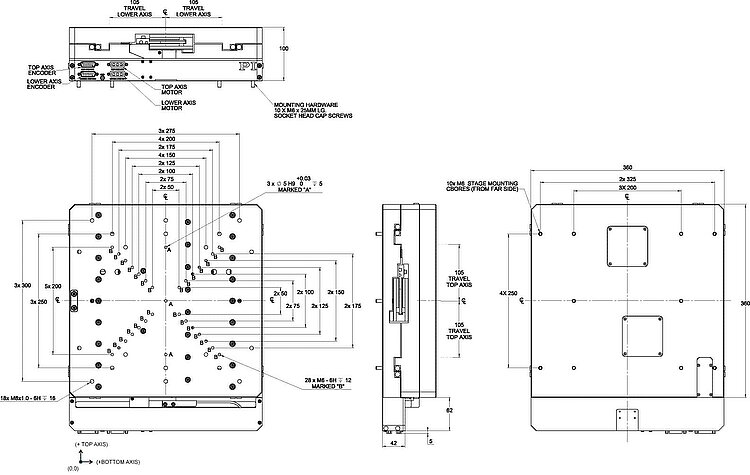

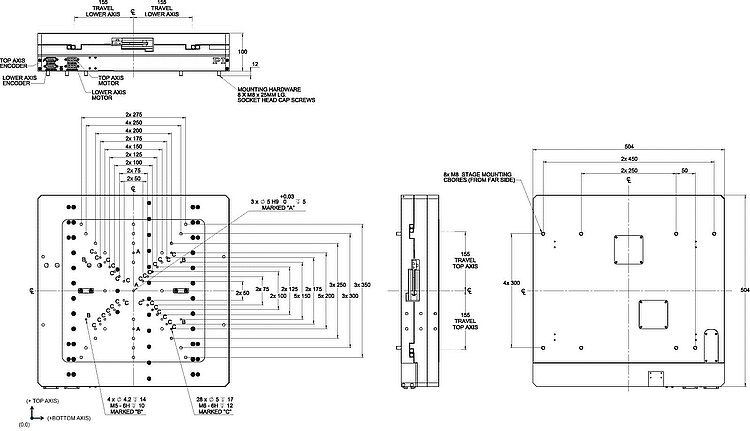

| Height | 80 mm | 100 mm | 100 mm | 80 mm | 100 mm | 100 mm | |

| Miscellaneous | V-781.110A1 | V-781.210A1 | V-781.310A1 | V-781.110B1 | V-781.210B1 | V-781.310B1 | Tolerance |

| Operating temperature range | 5 to 50 °C | 5 to 50 °C | 5 to 50 °C | 5 to 50 °C | 5 to 50 °C | 5 to 50 °C | |

| Connector | D-sub 3W3 (m) | D-sub 3W3 (m) | D-sub 3W3 (m) | D-sub 3W3 (m) | D-sub 3W3 (m) | D-sub 3W3 (m) | |

| Sensor connector | D-sub 15 (m) | D-sub 15 (m) | D-sub 15 (m) | D-sub 15 (m) | D-sub 15 (m) | D-sub 15 (m) | |

| Recommended controllers/drivers | A-81x, A-82x | A-81x, A-82x | A-81x, A-82x | A-81x, A-82x | A-81x, A-82x | A-81x, A-82x |

Note on straightness and angular errors: Dependent on the quality of the mounting surface, the payload, orientation, and external forces that act on the stage. Please contact PI for application-specific parameters. The specified values are static (no rotary motion during measuring) and without load.

Note on positioning accuracy: The specified values are based on the error compensation achievable with PI controllers. The positioner must be ordered with a controller from PI to reach these values. Accuracy values assume short-term duration and do not consider the long-term effects of thermal drift on the stage.

Note on velocity, acceleration, and permissible push force in Z: Can be limited by imbalance of the payload or the controller and the drive.

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Ultra-precision direct drive XY stage; ironless 3-phase linear motor; 210 mm × 210 mm travel range (X × Y); 500 N load capacity; 1000 mm/s × 1000 mm/s maximum velocity; incremental linear encoder, 1 nm sensor resolution, sin/cos, 1 V peak-to-peak

Ultra-precision direct drive XY stage; ironless 3-phase linear motor; 310 mm × 310 mm travel range (X × Y); 500 N load capacity; 1000 mm/s × 1000 mm/s maximum velocity; incremental linear encoder, 1 nm sensor resolution, sin/cos, 1 V peak-to-peak

Ultra-precision direct drive XY stage; ironless 3-phase linear motor; 110 mm × 110 mm travel range (X × Y); 100 N load capacity; 500 mm/s × 500 mm/s maximum velocity; absolute linear encoder, 1 nm sensor resolution, BiSS-C, 32 bit

Ultra-precision direct drive XY stage; ironless 3-phase linear motor; 210 mm × 210 mm travel range (X × Y); 500 N load capacity; 1000 mm/s × 1000 mm/s maximum velocity; absolute linear encoder, 1 nm sensor resolution, BiSS-C, 32 bit

Ultra-precision direct drive XY stage; ironless 3-phase linear motor; 310 mm × 310 mm travel range (X × Y); 500 N load capacity; 1000 mm/s × 1000 mm/s maximum velocity; absolute linear encoder, 1 nm sensor resolution, BiSS-C, 32 bit