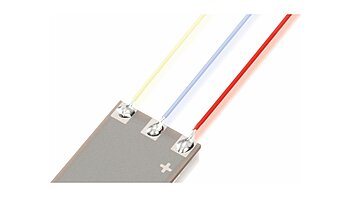

Standard contacts for piezo actuators are 100 mm stranded wires or soldering points. For each piezo element, different wires acc. to the AWG standard are used. Please observe the soldering instructions for each product.

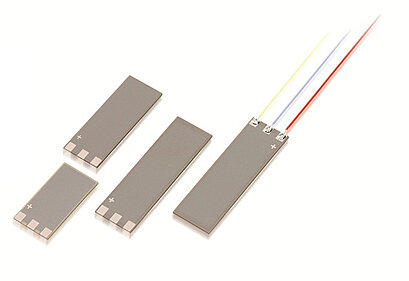

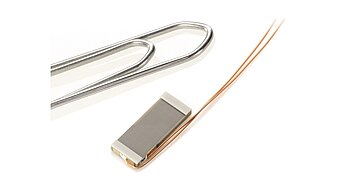

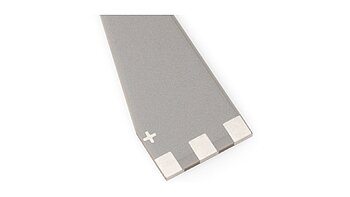

PICMA® Piezo Bender Actuators

Multilayer Bending Actuators with Large Displacement

PICMA® multilayer piezo bender actuators provide particularly large stroke in combination with high dynamics. Their piezo voltages are low, while their bimorph structure ensures bidirectional displacement.

The technology of monolithic PICMA® multilayer actuators is synonymous with high reliability and long lifetimes.

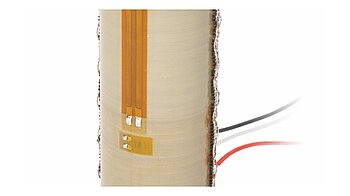

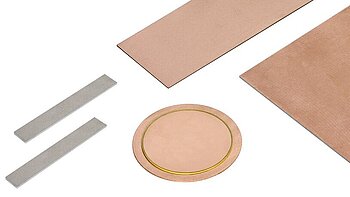

Customization

PICMA® piezo bender actuators are produced in a wide range of shapes. Depending on the application, they can also be assembled with adapted ceramic or metal end pieces, additional coating, temperature sensors, etc. On request, we gladly offer you customized products.

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI Ceramic sales engineer.

Downloads

Material Data

Technical Note PD410T0001

PD410 PICMA® Circular Bender Actuators

Piezoelectric Actuators

Components, Technologies, Operation